Which one to choose? Complete Guide to Flail Mower, Features and Functions

Introduction to Flail Mover

The Tractor-driven Flail Mower is the tool used by all farmers who must eliminate wild grasses, plant residues and brambles from their field, olive grove or vineyard. The Flail Mower cuts and shreds any plant residue, even well rooted in the soil, obtaining a clean and homogeneous field. Once the plant residues have been chopped, after passing through the machine, they become a useful fertiliser for the soil.

Main elements that make up a flail mower

A flail mower is mainly composed of:

- a Rotor

- a Shell

- a Transmission

- an Arc with 3 points of connection to the tractor

- a Stabilising element (roller or wheels)

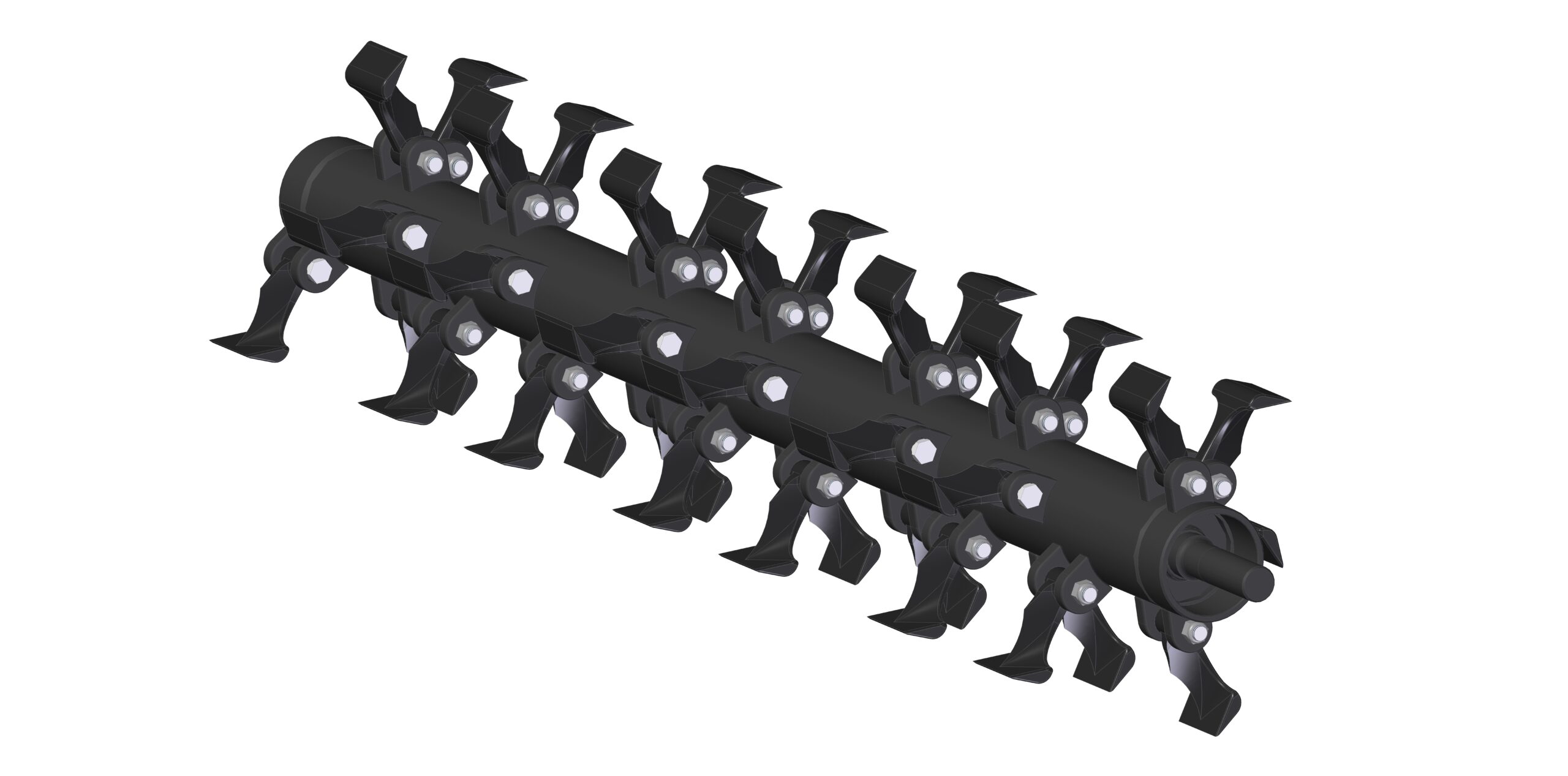

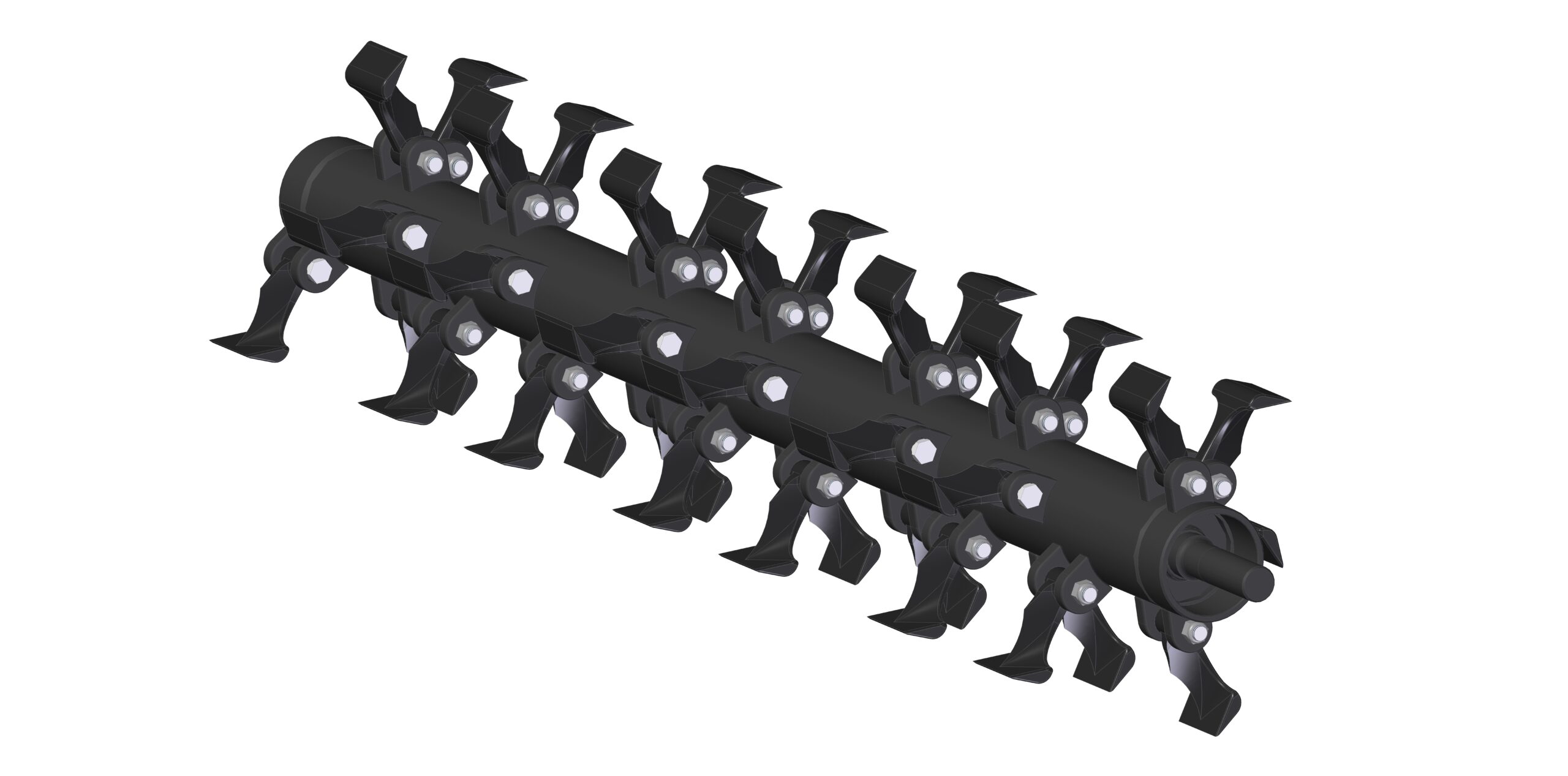

The Rotor

The rotor is the fundamental element for the work of the flail mower It consists of a central body to which the tools are applied: knives or clubs.

When the machine is running, the rotor rotates between 1,800 and 3,000 rpm, depending on the type of flail mower. The rotor contributes almost 50% of the overall weight and is the most expensive element of the machine. With the same machine width, there can be many different rotors.

The diameter of the rotor body tube is a fact that has a great impact on weight and performance. There is a direct relationship between peripheral shear speed and rotor tube diameter. The rotors with larger pipe diameters allow high peripheral shear speeds to be achieved, which helps to increase the working speed of the machine.

The Shell

The shell is the external part of the machine and serves to hold together all the elements that make up the flail mower. The rotor is placed inside the shell.

The shape of the shell affects the final size of the shredded material and the working speed.

Machines are available with:

- Simple shell consisting of a single sheet of folded sheet metal;

- Reinforced shells equipped with elements that strengthen the machines at the points of greatest wear;

- Double sheet metal shells characterised by two sheets of steel resting on each other, in contact, making the machine very resistant to the impact of stones.

The shredder with double shell is thus truly indestructible and suitable for use in adverse conditions.

TIERRE manufactures some double-shell machines in HARDOX. This means that the steel used for the inner part of the shell is high-strength and wear-resistant.

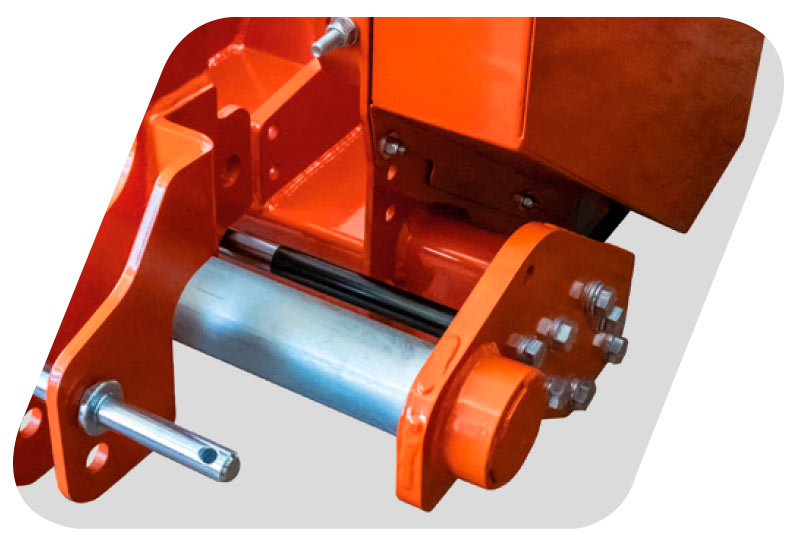

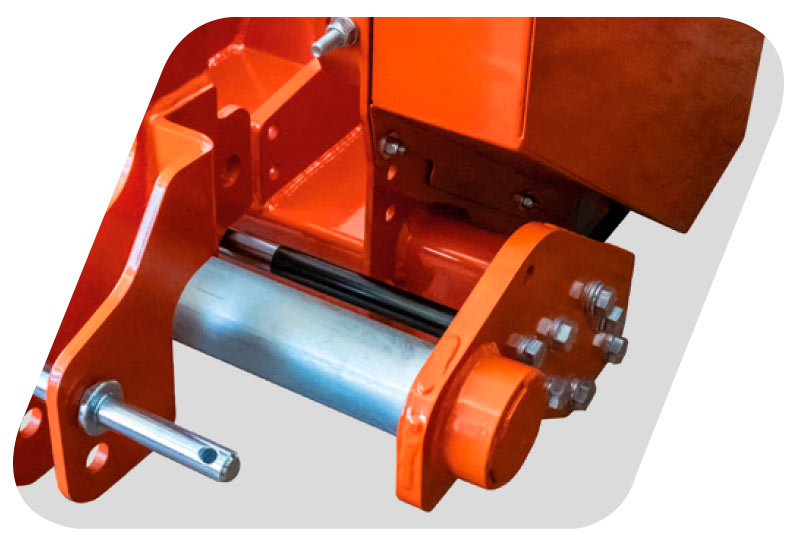

The Transmission

The transmission of a shredder is composed of

-

multiplier unit

-

pair of pulleys and drive belts.

Multiplier Unit

The multiplier unit consists of a cast iron casting inside which a conical torque is housed. The conical torque has the function of multiplying the number of revolutions coming from the tractor’s power take-off and then returning them to the pulleys.

A multiplier unit generally operates at 540 or 1000 revolutions. Inside the gearbox unit there is a safety device called “FREEWHEEL”. The freewheel that is located inside the gearbox assembly of the brush shredder is conceptually the same as the mechanism applied to the rear wheel of bicycles.

Its function is to stop the motion progressively when the tractor is switched off in order to safeguard the tractor and brush shredder.

Pair of pulleys and drive belts

The pair of pulleys and the drive belts are enclosed within a protective casing. The upper and lower pulleys generally have different diameters.

The purpose is to further multiply the revolutions coming from the multiplier unit. Belts are housed on the pulleys, which can vary both numerically and qualitatively depending on the type of brush shredder.

The belts also have the function of sliding in case there are significant impacts on the shredder rotor.

The 3-point connection arc

The 3-point connection arc is the element that allows the shredder to connect to the tractor. On the base of the arc are positioned what are called the first and second points. At the top of the arc there is a connection to the third point.

The connecting arcs can have different sizes. The dimensions of the arcs are standardised according to the international standards provided by ISO703

Displacement

Flail Mower can be divided into:

-

shredder with fixed attachment

-

shredder with manual displacement

-

shredder with hydraulic displacement

-

parallelogram shredder (embankment shredder)

The flail mowers equipped with displacement, whether manual or hydraulic, have an indicative translation of about 35-45 cm. They allow working projections of 60-70 cm with respect to the rear wheels of the tractor. Leaving the tractor allows it to get closer to the trees, so they are better at finishing, taking care of the edges of the fields and the banks. Shredders with the displacement guarantee a higher level of manoeuvrability.

The shredders can have a lateral projection with respect to the centre of the tractor of 3.5 m. Obviously, a shredder with hydraulic displacement can only be used if you have a tractor capable of supporting this feature, and therefore, one that has the hydraulic system.

Stabilisation

The stabilisation of the flail mower on the ground can be done by roller or wheels.

Tractor pairing

Tractors are mainly divided into 4 macro power categories

Category 1 – Below 75 hp

Category 2 – Between 76 and 147 hp

Category 3 – Between 148 and 295 hp

Category 4 – From 296 hp

These categories determine which equipment is applicable.

With a Category 2 tractor we could apply “at most” a Category 2 shredder or a Category 1 shredder. In addition, tractors are divided by field of application according to the shape of the wheels

and the size of the vehicle.

They can thus be suitable for

- Cereal farming

- Orchards

- Horticulture

- Green maintenance

- Earthmoving

- Municipality

- Viticulture

When choosing a brush shredder, first of all you need to know which tractor it will be combined with.

Field of application

The first thing to keep in mind is that all flail mowers perform the same function: they cut what is present on the surface to shred it and facilitate its absorption into the ground. Brush shredders NEVER work the ground.

The application of a brush shredder can therefore be:

- Cutting the grass

- Cutting pruning residues present in the soil (olive, vine, pear, apple)

- Cutting vegetable residues (carrots, potatoes, tomatoes)

- Cutting the stalks of tall plants (Corn, Sunflowers, Tobacco)

- Cutting woody residues (cotton)

- Cutting logs and stumps (trees)

Each type of flail mower is optimised only for one type of work.

TIERRE has a patent for a range of machines called ADAPTIVE GEOMETRY. Machines with ADAPTIVE GEOMETRY can change their intended use simply by making a few small adjustments. For example, PANTERA can work indistinctly on grass, pruning and cereals.

Cutting tools

There are 2 main categories of shredder cutting tools:

- knives

- clubs

Choice of knives

Knives are used when there are stalks or the volume of grass to be cut is very large. The cutting configurations can be with 2 knives (Y-shaped) or with 3 knives.

Choices of clubs

Clubs are used in all cases where woody residues are present and it is the most used tool in shredders. TIERRE has patented double-edged clubs. TIERRE clubs allow you to cut both horizontally and vertically, thus increasing the destructive capacity of the machine.

Heaviness of the Shredder

The heaviness of the shredder can help to understand some technical characteristics of the machine.

For example, for the working widths of 180 cm, TIERRE has the following brush shredders:

- Light series: LUPO 180 Shredder, 300 kg

- Medium series: PANDA 180 Shredder, 400 kg

- Medium – Heavy series: TIGRA 180 Shredder, 530 kg

- Heavy series: PANTERA 180 Shredder, 840 kg

In principle, the heavier a machine is, the more burdensome the work it can sustain. The weight of the machine, in relation to the category, determines which tractor may be most suitable for the machine.

What weight doesn’t say

Comparing different brush shredders only using the weight as a reference is a mistake that many make. A steel of the highest quality has the same weight as a steel of low quality. Poor components weigh exactly the same as high-performance components. TIERRE produces a large part of its machines with HARDOX wear-resistant steel.

Many components are made of high-performance structural steel.

The transmission units are those of the most important Italian companies, as well as the components.

TIERRE: there is a difference.

Accessories

Harvesting Rods

Harvesting rods are specific for shredding pruning and perform a lifting function from the ground to facilitate shredding.

Crampons are generally found on heavy brush shredders designed for pruning fruit trees.

Wear-resistant skids

These are skids to be applied to the sides of the flail mower to ensure that the machine “slides” on the grass without consuming the sides. Usually wear-resistant slides should be applied when it comes to cutting a lot of grass because it is abrasive.

Winemakers and fruit growers generally do not like to use mowers with skids because the latter can cut the base of the plant and ruin it. For this reason, the TIERRE machines can work both with the skids and without skids in order to meet the needs of each customer.

ANTI-BREAK

It is a mechanical system applied to the flail mowers that prevents damage, and therefore breaking, of the arms of the parallelogram when it accidentally hits trees or other types of obstacles.

Homokinetic Cardan Shaft

The homokinetic cardan shaft consists of a double joint at both ends. This type of cardan shaft ensures fluidity of movement, especially in the case of bank shredders, and makes it possible to reduce the mechanical stresses of the joints.

It is the accessory chosen by professionals who need to work long hours.